We use

cookies and similar technologies

to help give you the best experience on our site and to show you relevant advertising. If you continue to use this site, we’ll assume that you’re happy to receive all cookies

DX Engineering RT4500HD Heavy-Duty Rotators DXE-RT4500HD

SKU Part Number:

DXE-RT4500HD

£2,749.99

£2,291.66

Pre Order

Seen this product cheaper elsewhere?

Call 0345 2300 599X Engineering RT4500HD Heavy-Duty Rotator – Here is the ultimate azimuth positioning rotator, purpose-built to work flawlessly for many years in a vast majority of tower-mounted directional antenna systems. Every aspect of this rotator was specifically designed for high-strength, ease of installation, serviceability and longevity. This is THE rotator of choice for any radio enthusiast who desires an extremely capable and worry-free unit for their tower mast-mounted directional antennas.

The RT4500HD Heavy-Duty Rotator has capabilities that surpass most rotators available on the Amateur Radio market. In addition to an impressive list of features and benefits, it is especially noteworthy that this rotator does not have mechanical limit switches. Soft rotation limits are set as desired in the controller, to the limits of the installed antenna cables. If the antenna or the mast ever slips, simply reset the controller to the new center of rotation and recalibrate the rotational range. Climbing or antenna mast repositioning is not immediately required.

An Important Note About Rotator Capacity – Antenna Wind Area, expressed in square feet or square meters, is a specification that applies for tower loading, but it does not properly equate to rotator specifications. The appropriate specification for rotators is Rotational Torque. Antenna system size, boom and element lengths, antenna balance, as well as total antenna and mast weight, must all be considered to determine torque requirements. Total antenna wind area handling of the DX Engineering RT4500HD may be expected to be greater than 35-40 sq. ft. for very well-balanced antenna systems, while also using the appropriate torque calculations that account for total antenna system size and weight.

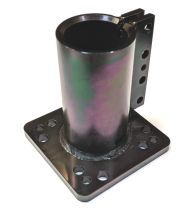

The part number DXE-RT4500HD is the stand-alone rotator unit only, which does not include a Top Mast Clamp. This allows for the selection of one of two different size Rotator Top HD Mast Clamps available, both also sold separately, that matches popular mast outside diameters (OD); DXE-RTMC-2 for 2-inch OD mast and DXE-RTMC-3 for 3-inch OD mast.

Similar part numbers with added suffixes represent combinations that include the DX Engineering RT4500HD Heavy-Duty Rotator along with either the 2-inch or the 3-inch Rotator Top HD Mast Clamp, as well as systems that also include either the DXE-RT-21DXE Digital Rotator Controller or the microHAM ARCO Advanced Rotator Controller. Rotator control cables and cable assemblies are sold separately.

Install the DX Engineering RT4500HD Heavy-Duty Rotator in your tower to take advantage of these features and benefits:

-Superior Rotational Torque > 4,400 in. lbs. with high ratio worm gear drive powered by an extra heavy-duty 24VDC motor

-Exceptional Braking Torque >18,500 in. lbs. by high ratio gear reduction that prevents rotation of the mast-mounted antenna system due to wind

-Very High Vertical Load Capacity — internal needle thrust bearing handles up to 2,000 lbs.

-High-compression Heavy-Duty Top Mount Mast Clamps available for 2-inch OD or 3-inch OD masts

-Precision Movement — accuracy within +/-0.1 degrees with high-resolution pulse counter controller

-Easy Maintenance — access panel allows service of pulse counter switch without removing the rotator from the tower

-Built for Longer Life — all steel gears are hardened; high-load gears are welded onto their shafts to prevent slippage; larger main gear provides increased strength

-Weather-Protected — sloped powder coated body sheds water; seals at the output shaft, intermediate plate and access panel keep moisture out; weep holes make sure it stays dry

-Worry-Free Installation — four-bolt standard mount; this triangular-shaped rotator is ideally sized to fit inside any G-series ROHN tower, including 25G (but the RT4500HD easily handles larger antenna systems than 25G will withstand).

-Works with High-Quality Controllers — Optional DX Engineering Rotator Controller DXE-RT21DXE or other 24VDC, Pulse Counting Programmable Controllers including Green Heron Engineering and microHAM ARCO Advanced Rotator Controller

Specifications, DXE-RT4500HD Heavy-Duty Rotator

-Maximum Torque: Over 4,400 in-lbs. @ 24VDC

-Braking Torque: Over 18,500 in-lbs.

-Vertical Load: 2,000 lbs., maximum

-Rotating Range: Unlimited (limited by the range of installed coaxial cables)

-Rotational Speed: 61 seconds/revolution (360 degrees) @ 24VDC, max.

-Resolution: 0.1 degree, nominal (dependent upon controller)

-Travel Accuracy: 0.1 degree

-Pulse Counter Ratio: 4,814 pulses per revolution (required for third-party controller programming)

-Antenna Mast Clamp: 2 in. OD DXE-RTMC-2 or 3 in. OD DXE-RTMC-3, available with rotator and separately

-Voltage: 24VDC

-Current: 3.1 Amps, nominal, during rotation

-Weight: 22 lbs. without hardware or mast clamp; 27 lbs. with hardware and 2 in. Mast clamp

-Width: 7.970 in. apex to side; 8.855 in. apex to apex (fits inside Rohn 25G and larger)

-Height, without clamp: 9.205 in. from base to top of mast platform

-Control Wire: 4 Cond. Cable, 2 @ 12 AWG (motor) + 2 @ 18 AWG (pulse counter) for controller to rotator total length up to 400 ft., 4-Cond. Male weatherproof locking shielded connector installed on rotator pigtail; Female cable-mount mating connector supplied. Extension cables available separately.

Specifications

Brand:

Manufacturer's Part Number:

DXE-RT4500HD

Part Type:

Product Line:

DXE Part Number:

DXE-RT4500HD

Wind Load Rating (Inside Tower):

Over 35 sq. ft.

Rotator Turning Power:

Over 4,400 in.-lbs.

Wind Load Rating (Mast Mounted):

N/A

Maximum Antenna Mast Diameter:

3.000 in.

Directional Display Type:

None

Rotator Brake Type:

Gear reduction

Rotator Brake Power:

Over 18,500 in.-lbs.

Rotator Bearing Type:

Precision Needle Bearings

Control Cable:

4-conductor

Rotator Height:

9.205 in.

Rotator Width:

8.855 in. (apex to apex)

Rotator Weight:

22.00 lbs.

Quantity:

Sold individually.

DX Engineering RT4500HD Heavy-Duty Rotators

DX Engineering RT4500HD Heavy-Duty Rotator – The ultimate azimuth positioning rotator, purpose-built to work flawlessly for many years in a majority of tower mounted directional antenna systems. Every aspect of this rotator was designed for high-strength, ease of installation, serviceability and longevity. This rotator is extremely capable and worry-free for tower mast mounted directional antennas.

The RT4500HD Heavy-Duty Rotator has capabilities that rival most rotators available on the Amateur Radio market. With an impressive list of features and benefits, it is noteworthy that this rotator does not have mechanical limit switches. Soft rotation limits are set in the optional controller to match the limits of the installed antenna cables. If the antenna or the mast ever slips, simply reset the controller to the new center of rotation and recalibrate the rotational range. Climbing or antenna mast repositioning is not immediately required.

The part number DXE-RT4500HD is the stand-alone rotator unit only, which does not include a Top Mast Clamp. This allows for the selection of one of two different size Rotator Top HD Mast Clamps available, both also sold separately, that matches popular mast outside diameters (OD); DXE-RTMC-2 for 2-inch OD mast and DXE-RTMC-3 for 3-inch OD mast. Similar part numbers with added suffixes represent combinations that include the DX Engineering RT4500HD Heavy-Duty Rotator with either the 2-inch or the 3-inch Rotator Top HD Mast Clamp. Other part numbers include either the DXE-RT-21DXE Digital Rotator Controller or the microHAM ARCO Advanced Rotator Controller. Rotator control cables and cable assemblies are sold separately.

Features and benefits of the extremely durable RT4500HD Heavy-Duty Rotator:

• Superior Rotational Torque > 4,400 in. lbs. with high ratio worm gear drive powered by an extra heavy-duty 24VDC motor

• Exceptional Braking Torque >18,500 in. lbs. by high ratio gear reduction that prevents rotation of the mast mounted antenna system due to wind

• Very high Vertical Load Capacity — internal needle thrust bearing handles up to 2,000 lbs.

• High-compression Heavy-Duty Top Mount Mast Clamps are available for 2-inch OD or 3-inch OD masts

• Precision Movement — accuracy within +/-0.1 degrees with high resolution pulse counter

• Easy Maintenance — access panel allows service of pulse counter switch without removing the rotator from the tower

• Built for Longer Life — hardened steel gears welded onto shafts prevent slippage and shearing of key pins; larger main gear provides increased strength

• Weather-Protected — sloped body sheds water; seals at the output shaft, the intermediate plate and the access panel keep moisture out; weep holes make sure it stays dry

• Worry-Free Installation — four-bolt standard mount; this triangular-shaped rotator fits inside ROHN 25G towers, but the RT4500HD easily handles larger antenna systems than 25G will handle.

• Works with High-Quality Accessories—Optional DX Engineering DXE-RT-21DXE Digital Rotator Controller, or the microHAM ARCO Advanced Rotator Controller or other 24VDC Pulse Counting Programmable Controller.

Install the rotator that provides the most accurate and dependable operations – the DX Engineering RT4500HD Heavy-Duty Rotator.

Shipping:

We have several shipping options for our products, including next-day and Saturday/Sunday delivery for certain items. Please see these options at checkout.

Returns:

If you have any equipment that needs to be returned to Martin Lynch & Sons, please fill out the form below:

Upon receipt of goods you have 14 days to return goods however the goods must be returned in original packaging and care must have been taken with the goods you wish to return. Under distance selling regulations you are not entitled to any refund on carriage charges or modification charges made at your request.

Warranty Terms and Conditions

Outside of the 14 faulty return period, returned items cannot be accepted, unless covered by manufacturer's warranty. We will repair as much as possible on site however in exceptional circumstances products may have to be returned to the manufacturer of distributor.

For repairs/replacements under manufacturer’s warranty for any item please download a ML&S return form from the link above and return to ML&S with the faulty product.

International Warranty information

Warranty service for items we sell is available in the U.K. only, unless otherwise noted. It is your responsibility to pay freight for returned items to the U.K. and back to you for desired warranty coverage. All of our NEW products come with a minimum 12 month warranty, (Yaesu & Icom 24 months), with up to 90 days on second-hand equipment. Items returned for service must state "returned goods for repair" on the return air waybill or U.K. import customs duties apply and will be added to your invoice. For more info about returning items please contact our customer help desk, [email protected]