We use

cookies and similar technologies

to help give you the best experience on our site and to show you relevant advertising. If you continue to use this site, we’ll assume that you’re happy to receive all cookies

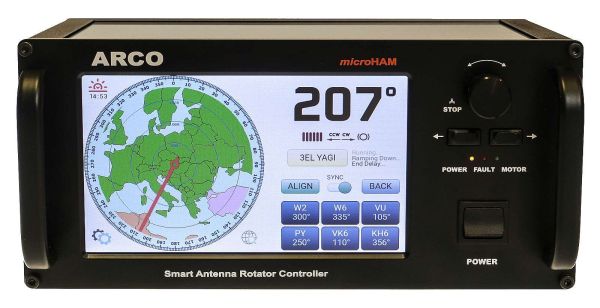

Microham Arco Smart Antenna Controller

SKU Part Number:

MHAM-ARCO

Next batch due April 2024.

The ARCO is a modern rotator controller designed for reliable operation with virtually any rotator ever made,...

Read More

Read More

£799.99

£666.66

Pre Order

Seen this product cheaper elsewhere?

Call 0345 2300 599Next batch due April 2024.

The ARCO is a modern rotator controller designed for reliable operation with virtually any rotator ever made, commercial or home brew.

ARCO provides a lot of unique present day functions, not yet available in any other controller. Rotator motion is carefully controlled using auto-adapting, smoothly graduating/decaying speeds, reducing inertial stress, and prolonging lifetime of the rotator, antennas and tower.

Built to last, built for security, built for total satisfaction!

Have pleasure with new features, bringing your gear extra protection and longer life!

ARCO is a completely self-contained stand alone rotator controller not requiring computer or any external device or power supply for setup and operation, while providing a wide selection of interfaces for remote control when necessary. It features several ways of controlling azimuth or elevation heading using uncluttered graphical user interface on the 7” touch screen. Azimuth heading is displayed on a great circle map, user centered to the rotator installation location, with four different radius settings, live grey line projection, several coloring options and automatic day/night color schemes. The controller supports

Touch'n Turn feature, fastest possible heading entry by simple touching desired direction on great circle map. Than classic tactile front panel CW and CCW buttons, Point and Shot knob and heading entry keypad, either virtual on the touch screen or hardware, connected to the USB host port on the ARCO.

Along with the manual control, ARCO offers rich connectivity for the computer using standard RS-232 port, USB serial port not requiring any driver installation on Windows 10, macOS, and Linux, and Ethernet port to enable control over Internet.

For rotator position feedback, ARCO supports wide range of the absolute and relative sensors including rheostat, potentiometer, reed contact, Hall sensor, and PWM sensor. Additional digital sensor port provides three differential lines supporting RS-485 communication as well as single ended push-pull and open collector connection for various quadrature encoders. With high resolution sensors positioning accuracy is 0.1º.

For the motor control, ARCO uses high current, 4-channel PWM driver with overload, short circuit and overheat protections, combined with automatically operated, current monitoring internal power supply, preventing driver damage caused by operation failures. This combination is capable of driving safely any DC motor up to 48V or any AC motor up to 24V, including innovative brake control reducing solenoid heat.

Motor start and stop uses configurable, ultra-fine gradual speeds ramps, significantly reducing inertial forces stress to the rotator, tower and antennas, prolonging their lifetime. Gradual speed control uses auto-adapting procedure considering variable, dynamically changing resistance caused by wind or ice.

For its basic operation, ARCO uses built-in linear supply for silent, interference free operation. Separate built-in power supply for the motor is selectively controlled and entirely turned off when motor does not turn, to avoid causing any possible interference to the sensitive receivers. For high voltage or high power motors ARCO provides common control outputs for inverters as well as industry standard MODBUS RTU control. All rotator settings including compensation for power loss in the motor cables are menu driven, comfortably without requiring to open cover and change some internal wiring.

Networking is another strong point of ARCO. ARCO supports not only LAN networking but allows to build a simple but powerful, isolated two-wire local LINK bus, coupling multiple ARCO controllers together for automated stacks tracking, multi-directional beaming, and counter rotation for rotating towers.

Unique feature of ARCO is a direct control of rotators connected to another ARCO controllers, located either on the same LINK bus or anywhere in the world using Internet connection. All this complex control is greatly simplified by using just two, easy to handle SYNC and ALIGN buttons, and single ANTENNA button which allows to choose either one of three antennas installed on the same rotator with different heading offsets, or any other antenna present on the local LINK network through another ARCO, or on a remote LINK network through ARCO controller connected over the Internet.

For unattended remote operation over the Internet, ARCO offers autonomous parking function and physically disconnects all wires coming to the rotator port from the rotator hardware when connection is over, breaks, or if ARCO goes to the power down mode, in order to minimize possible damage by high static or nearby lightning during storms.

Firmware provides wide range of additional protections and self explaining error messages for quick troubleshooting if any failure happens. All of this packed in a full aluminum, compact enclosure with always free firmware updates.

Specifications

POWER INPUT

INPUT POWER: 500 VA max. IEC 60320, C14 (E) socket, filtered

LINE VOLTAGE: 90-130 VAC / 215-245 VAC, internally switchable

FREQUENCY: 50/60 Hz

ROTATOR

MOTOR OUTPUT: 4x isolated PWM output, max. 48 V, max. 7 A

SENSOR INPUT: 0-9 V, max. 16 kHz

REFERENCE OUTPUT: 9 V, max. 18 mA (shorted)

SENSOR ADC RESOLUTION: 2x 12 bit, 64x oversampling, 10 bit DAC for offset control

DIGITAL SENSOR: 3x RS-485, 1x MOD bus RTU, 1x 0-10 V analog output, 1x 12 VDC, 0.5 A auxiliary output

LINK: CAN bus

COMPUTER

USB B: USB 2.0, full speed, CDC compliance

USB A: USB 2.0, full speed, mass storage, keyboard HID support

ETHERNET: IEEE 802.3, 100BaseTX, auto MDI/MDIX

SERIAL: RS-232

GENERAL

DIMENSIONS: W-265 mm D-150 mm H-125 mm

WEIGHT: 2.85 kg net

Shipping:

We have several shipping options for our products, including next-day and Saturday/Sunday delivery for certain items. Please see these options at checkout.

Returns:

If you have any equipment that needs to be returned to Martin Lynch & Sons, please fill out the form below:

Upon receipt of goods you have 14 days to return goods however the goods must be returned in original packaging and care must have been taken with the goods you wish to return. Under distance selling regulations you are not entitled to any refund on carriage charges or modification charges made at your request.

Warranty Terms and Conditions

Outside of the 14 faulty return period, returned items cannot be accepted, unless covered by manufacturer's warranty. We will repair as much as possible on site however in exceptional circumstances products may have to be returned to the manufacturer of distributor.

For repairs/replacements under manufacturer’s warranty for any item please download a ML&S return form from the link above and return to ML&S with the faulty product.

International Warranty information

Warranty service for items we sell is available in the U.K. only, unless otherwise noted. It is your responsibility to pay freight for returned items to the U.K. and back to you for desired warranty coverage. All of our NEW products come with a minimum 12 month warranty, (Yaesu & Icom 24 months), with up to 90 days on second-hand equipment. Items returned for service must state "returned goods for repair" on the return air waybill or U.K. import customs duties apply and will be added to your invoice. For more info about returning items please contact our customer help desk, [email protected]